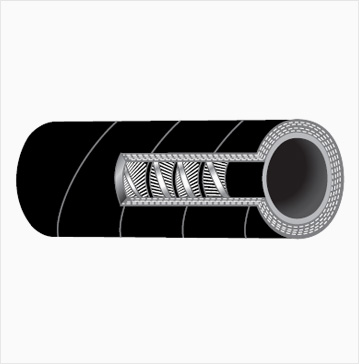

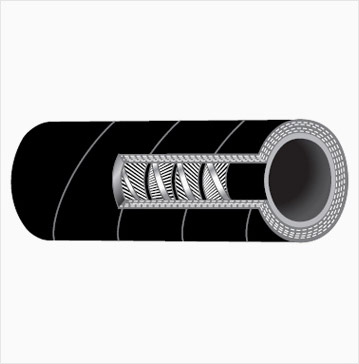

Chemical Hose

Specification

IS 7654 / 1975

Type I - Conveying diluted chemicals

Construction

Tube:

Natural Rubber

Reinforcement :

Multiple plies rubber impregnated strong woven fabric with helical steel wire, full-vacuum and discharge pressure, that vary according to size. Flexible construction keeps hose round when bent, reducing kinking and damaging

Cover :

Black outer rubber cover resists abrasion, sunlight and weather

Type II - Conveying concentrated chemicals

Construction

Tube:

Hypalon

Reinforcement :

Multiple plies rubber impregnated strong woven fabric with helical steel wire, full-vacuum and discharge pressure, that vary according to size. Flexible construction keeps hose round when bent, reducing kinking and damaging

Cover :

Hypalon resists abrasion, sunlight and weather

Application

For suction and discharge service handling many inorganic acids, except strong oxidizing agent. Withstands most salts and alkalies.

End Connection

Couplings must be selected for corrosion and pressure

For special application alternate construction can be supplied.

Tube:

Nitrile, Neoprene, Butyl, SBR, EPDM, Thiokol

Cover :

Nitrile, Neoprene, Butyl, SBR, EPDM, Thiokol

- I.D. Inches

- I.D. mm

- No. of plies

- Working Pressure psi

- Minimum bend radius mm

- 3/4

- 20

- 4

- 150

- 160

- 1

- 25

- 4

- 150

- 200

- 3/4

- 20

- 4

- 150

- 160

- 1

- 25

- 4

- 150

- 200

- 3/4

- 20

- 4

- 150

- 160

- 1

- 25

- 4

- 150

- 200

- 3/4

- 20

- 4

- 150

- 160

- 1

- 25

- 4

- 150

- 200

- 3/4

- 20

- 4

- 150

- 160

- 1

- 25

- 4

- 150

- 200

- 11/4

- 32

- 4

- 150

- 250

- 13/8

- 35

- 4

- 150

- 280

- 11/2

- 38

- 4

- 100

- 300

- 13/4

- 45

- 4

- 100

- 360

- 2

- 50

- 4

- 100

- 400

- 21/2

- 63

- 4

- 100

- 500

- 23/4

- 70

- 4

- 100

- 560

- 3

- 75

- 4

- 100

- 600

- 31/2

- 88

- 4

- 100

- 700

- 4

- 100

- 4

- 100

- 800

- 41/2

- 113

- 5

- 100

- 900

- 5

- 125

- 5

- 100

- 1000

- 6

- 150

- 6

- 100

- 1200

- 8

- 200

- 6

- 100

- 1600

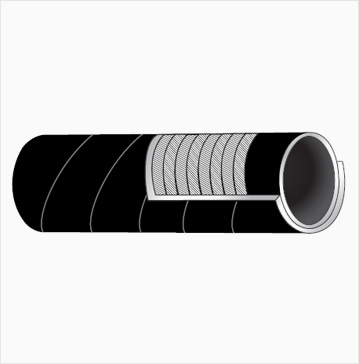

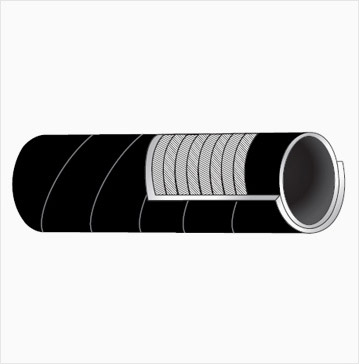

Delivery (Acid and Alkali Hose) (GCD)

Specification

IS 7654 / 1987

Type I - Conveying diluted chemicals

Construction

Tube:

Natural Rubber

Reinforcement :

Multiple plies rubber impregnated strong woven abric or yarn braided

Cover :

Black outer rubber cover resists abrasion, sunlight and weather

Ends :

The ends of the hose in length shall be securely sealed with rubber, 1.5 mm in thickness to prevent liquids coming into contact with the fabric reinforcement

Type II - Conveying concentrated chemicals

Construction

Tube:

Hypalon

Reinforcement :

Multiple plies rubber impregnated strong woven fabric or yarn braided

Cover :

Hypalon resists abrasion, sunlight, weather and ozone

Ends :

The ends of the hose in length shall be securely sealed with rubber, 1.5 mm in thickness to prevent liquids coming into contact with the fabric reinforcement

End Connection

Couplings must be selected for corrosion and pressure

Application

For special application alternate construction can be supplied

Tube:

Nitrile, Neoprene, Butyl, SBR, EPDM, Thiokol.

Cover :

Nitrile, Neoprene, Butyl, SBR, EPDM, Thiokol.

- I.D. Inches

- I.D. mm

- No. of plies

- Working Pressure psi

- 3/4

- 20

- 4

- 150

- 1

- 25

- 4

- 150

- 11/8

- 28

- 4

- 150

- 11/4

- 31

- 4

- 150

- 13/8

- 35

- 4

- 150

- 11/2

- 38

- 4

- 100

- 13/4

- 45

- 4

- 100

- 2

- 50

- 4

- 100

- 21/4

- 56

- 4

- 100

- 21/2

- 63

- 4

- 100

- 23/4

- 70

- 4

- 100

- 3

- 76

- 4

- 100

- 31/2

- 88

- 4

- 100

- 4

- 100

- 4

- 100

- 5

- 125

- 5

- 100

- 6

- 150

- 6

- 100

Product Categories

- Stainless Steel Hoses

- Rubber Hoses

- XLPE HOSES

- Steam Hose

- Oil Suction & Discharge Hose

- Liquified Petroleum GAS (LPG) Hose

- Chemical Hose

- Phosphoric Acid Suction & Discharge Hose (GPS)

- Carbon Free Hose (GCF)

- Brewery & Cermery Hose (GBC)

- Cable / Furnace Coolant Hose (GFC)

- Air, Pneumatic, Rock Drill Hose

- Sand / Shot Blasting & Cement Grounting Hose (GSC)

- Sand and Gravel Hose (GSG)

- Water Suction Hose

- High Pressure Hydraullic Hose

- Composite Hoses

- PTFE Hoses

- Expansion Joints

- Flange Guards

- PTFE Lined Pipes & Fittings